Technical details

The level of contamination of a component is not a fixed value, it is a temporary condition that is influenced by many factors.

According to the type of component and its application, the level of solid surface contamination may vary considerably. The problem of the cleanliness of components is becoming increasingly important due to the request for ever-better performances of systems.

Origin of the contaminant

-

Residues left following mechanical processes

-

Contamination coming from an external environment

-

Contamination generated during assembly

-

Contamination generated during the testing/running-in phase

Problems caused by the contaminant

-

High degree of likelihood of undergoing catastrophic failures during the first hours of operation

-

Reduced service life of system components

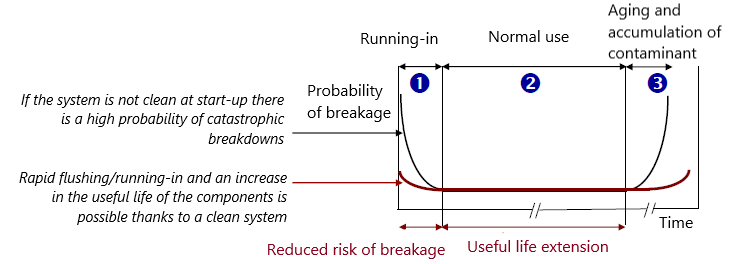

The so-called “bathtub curve” represents the qualitative aspects of the trend of the failure rate during the service live of a complex system. As for the problems mentioned above and, as shown in the curve below, by increasing the degree of cleanliness inside the component, it is possible to considerably extend its service life.

The measurement of the level of contamination of component makes it possible to check whether the production process is appropriate and under control. The level of cleanliness of a component is measured in accordance with a pre-defined standard, in order to verify whether required technical specifications have been achieved.

Over recent years, several international standards have been developed regarding the cleanliness of components and their relative contamination. A list of the standards of reference that guarantee operativeness and compliance with the OilSafe quality policy: